Filter products

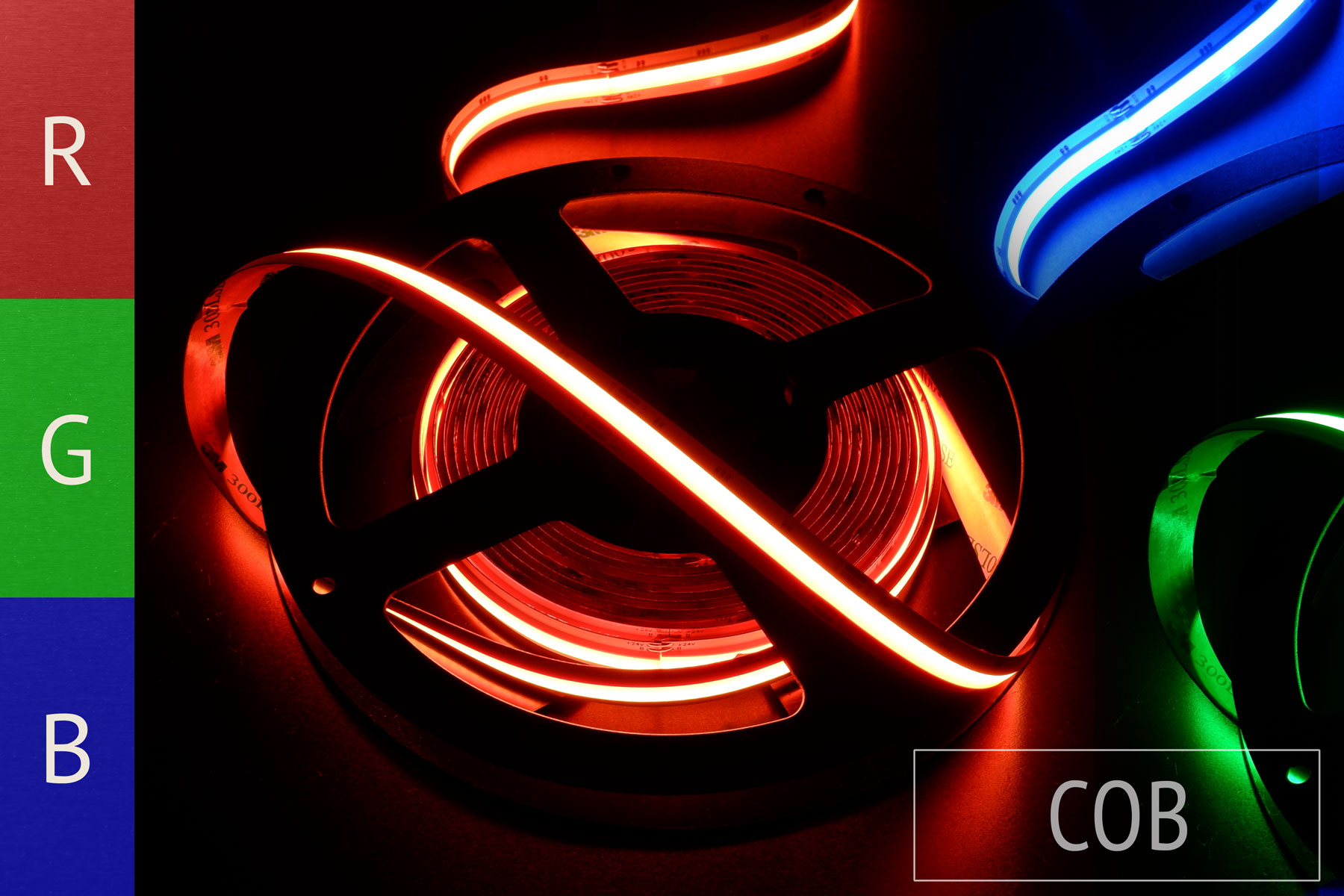

LED-Strips colour

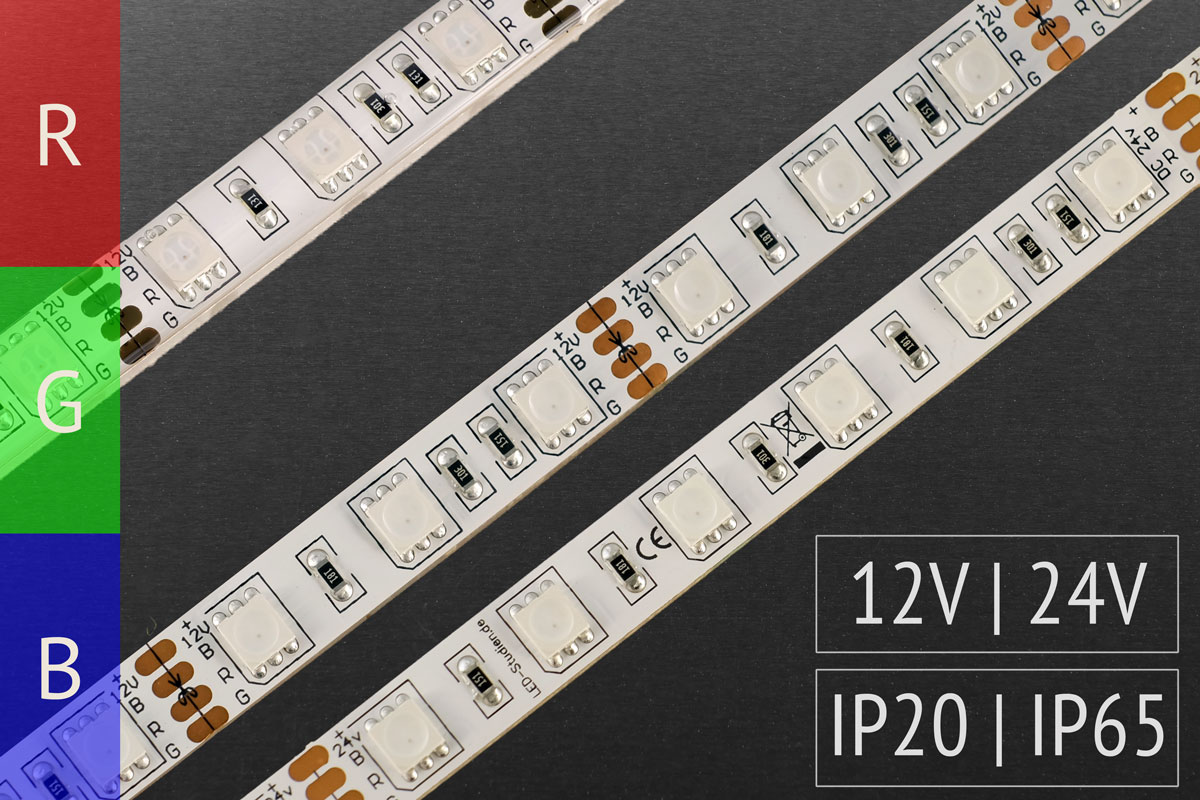

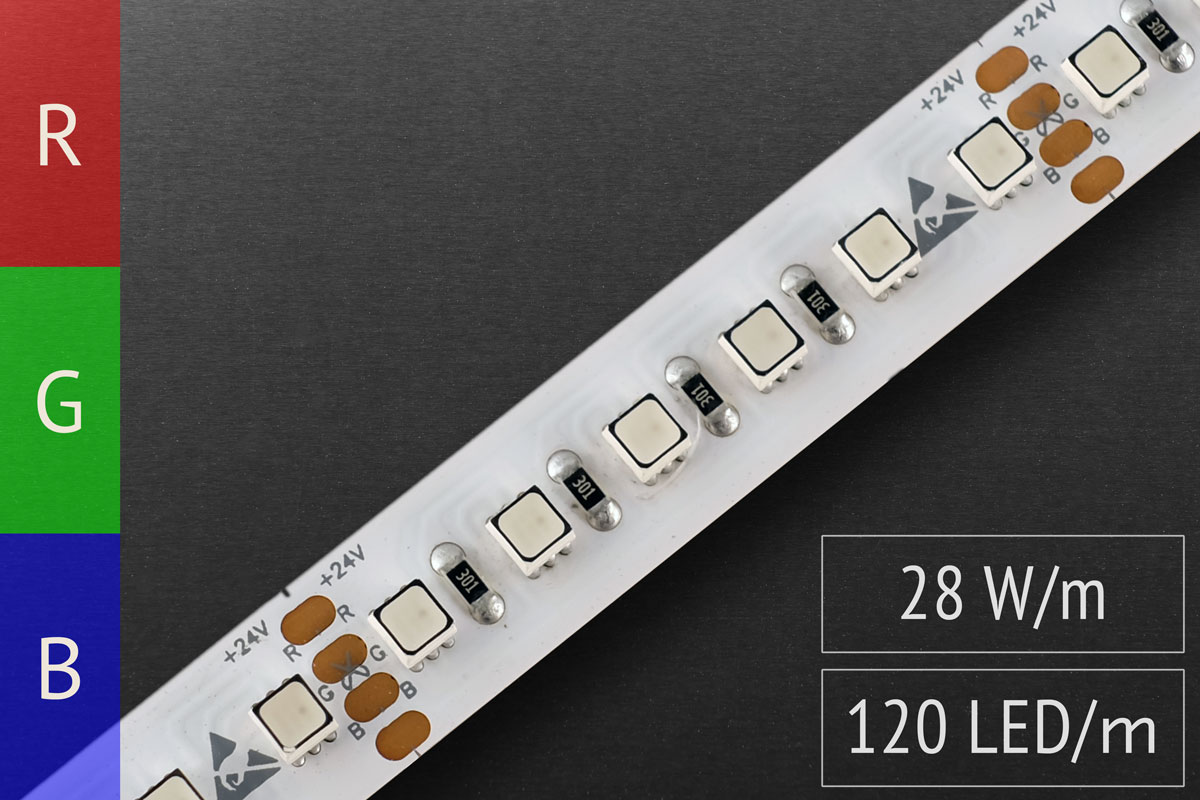

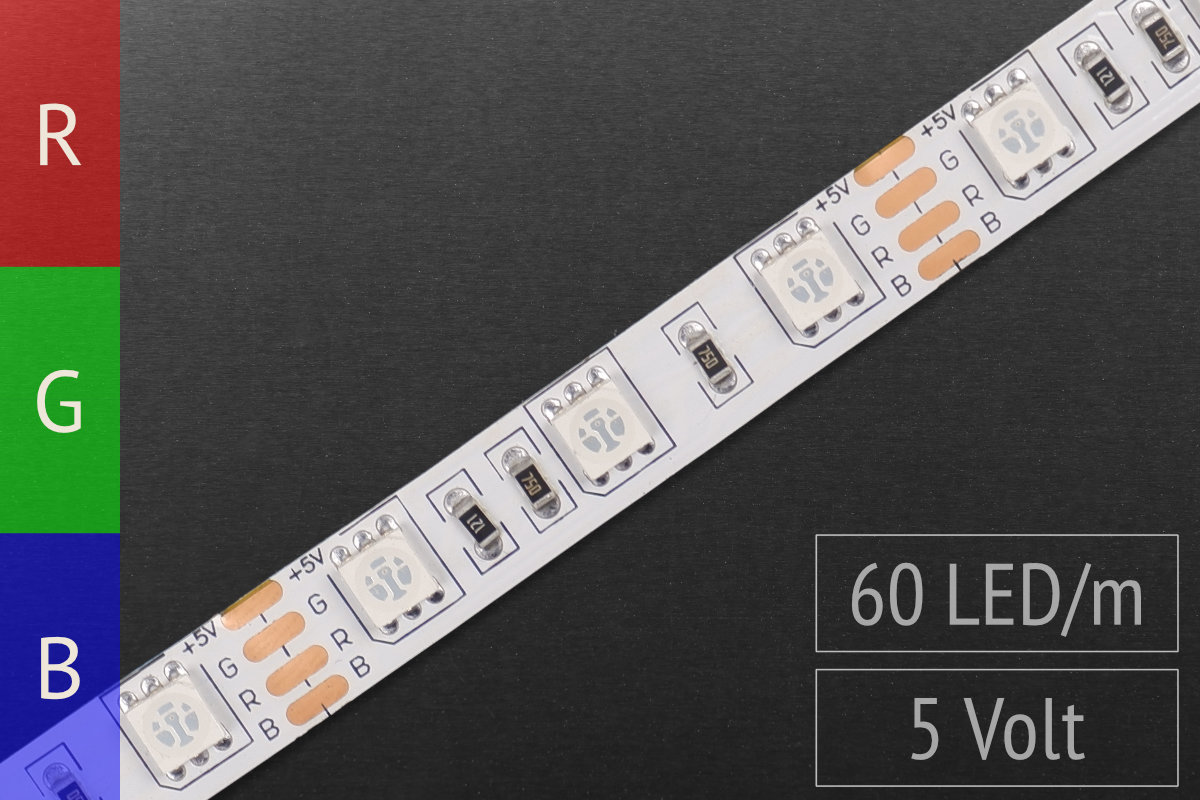

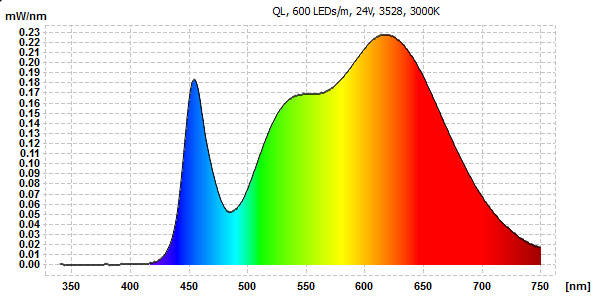

LED strips with RGB (red, green, blue) LEDs are ideally suited for freely adjusting any colour and are therefore the right choice when it comes to effect lighting. However, do not use RGB strips for general lighting. Although it is possible to create white tones by mixing red, green and blue in the right ratio, this will always be an inferior, unnatural white with very poor colour rendering.

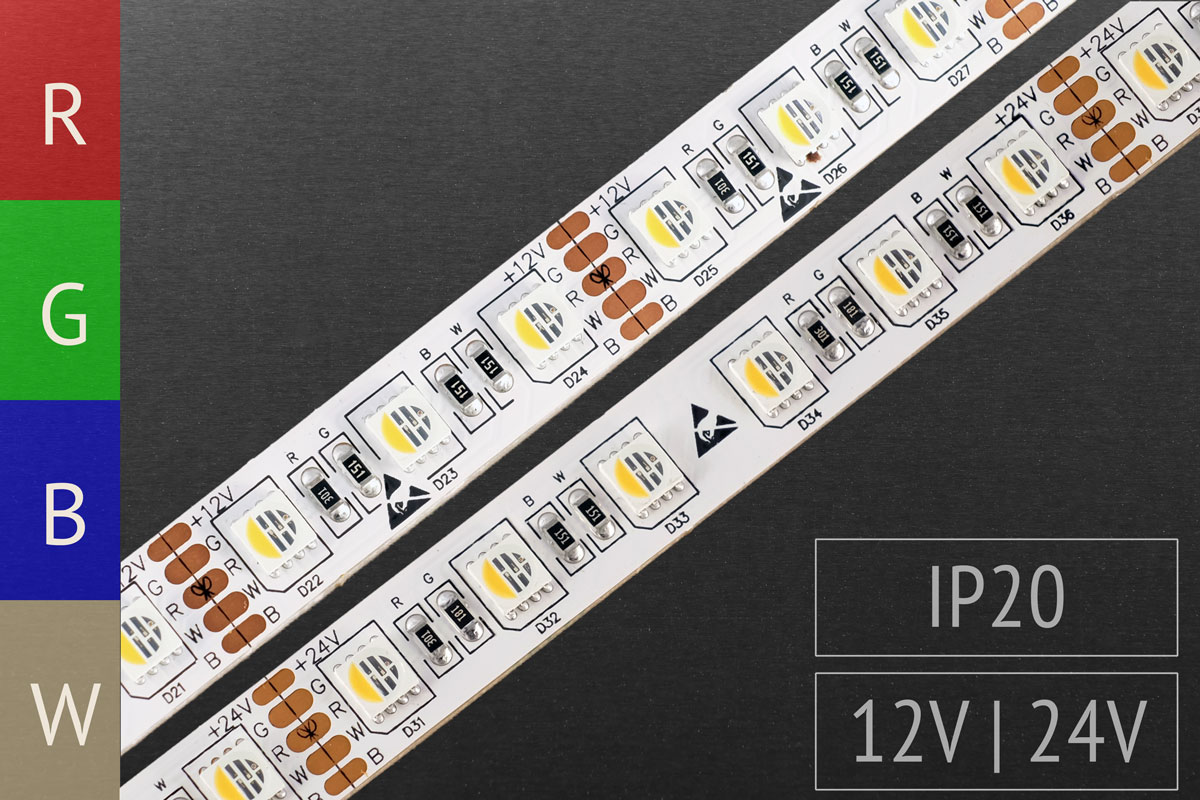

If you want to realise freely adjustable lighting that can produce both high-quality white and effect colours, choose RGBW strips. These have an additional white LED and thus produce a high-quality, colour-neutral white, as well as a filled-in light spectrum with good colour rendering.

Notes:

To control the colour effects, we offer a wide range of high-quality RGB & RGBW drivers.

The product group "LED strips" can also be found under the synonyms Flexband, LED band, LED strip or LED stripe.

Content: 5 Meter (€17.00* / 1 Meter)

Content: 5 Meter (€17.00* / 1 Meter)

Content: 5 Meter (€21.80* / 1 Meter)

Content: 5 Meter (€25.80* / 1 Meter)

Content: 5 Meter (€16.50* / 1 Meter)

Content: 5 Meter (€16.50* / 1 Meter)

Content: 5 Meter (€18.50* / 1 Meter)

Content: 5 Meter (€24.00* / 1 Meter)

Content: 5 Meter (€15.00* / 1 Meter)

Content: 5 Meter (€30.00* / 1 Meter)

Content: 5 Meter (€24.00* / 1 Meter)

Control

Special LED controllers, such as our LK55 or the ZigBee variant LK115-U, are needed to adjust the colour temperature. The LK55 offers various radio control options, such as handheld remote controls and wall-mounted models. The LK115-U is designed for control via app (e.g. PHILIPS HUE or ALEXA). Controllers for other smarthome systems such as KNX, DALI, EnOcean, Zigbee etc. are also available. As well as variants for DMX.

Of course, these controllers allow flexible dimming from 0 - 100 in addition to setting the colour temperature.

What is the difference between the individual LED strips?

Depending on the application, you should select the appropriate LED tape from our range. Important criteria are:

What do the indications "3in1" and "4in1" on the LED strips mean?

Older RGB LED strips used separate LEDs for red, green & blue, which were mounted next to each other at sometimes larger distances on the flex strip. With shorter distances (e.g. for indirect lighting or in combination with milky covers on aluminium profiles), this led to unclean colour mixes and multicoloured shadows.

Modern RGB LED strips use 3in1 LEDs in which red, green & blue LED chips are installed in a single LED. In this way, perfect colour mixing is achieved even at the shortest distance.

RGBW LED strips use the same concept with 4in1 LEDs. In addition to the RGB chips, a white LED chip is also installed in a single LED.

What is the advantage of "COB"?

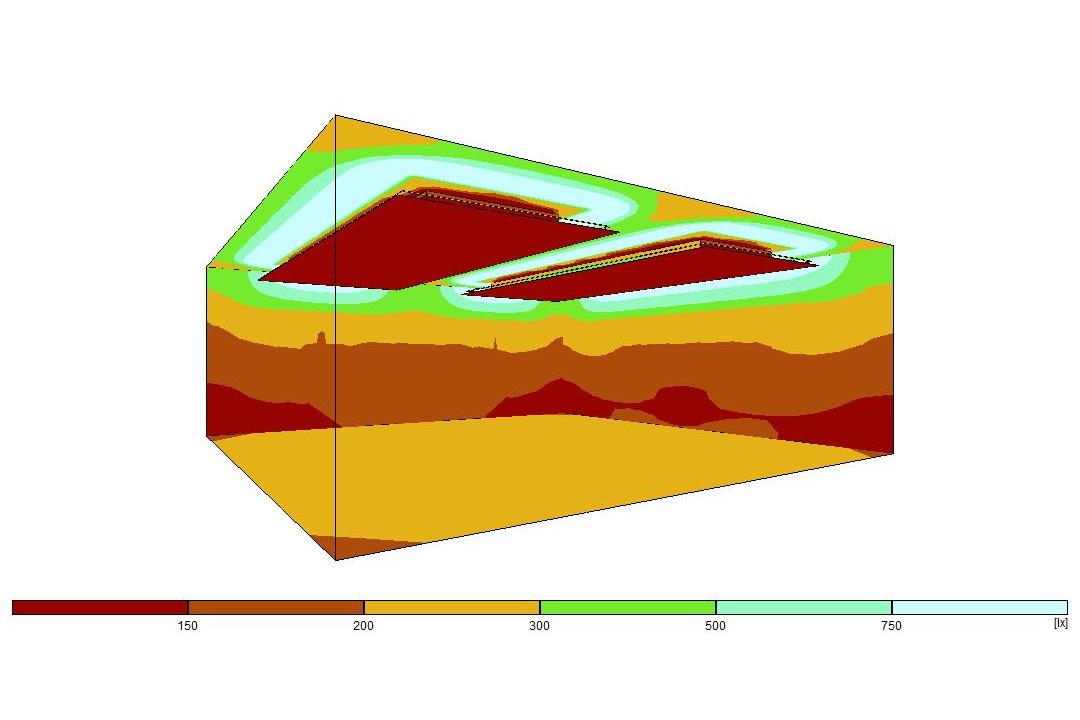

COB LED strips have no visible individual LEDs. The chips are covered with a phospore layer over the entire 5m roll, creating a completely uniformly illuminated strip of light. This is particularly advantageous for all applications in visible areas or where the LEDs are a very short distance from the wall or ceiling.

What are NEONFLEX Stips?

In NEONFLEX strips, the LED strips are encased in a milky-white silicone sleeve. This means that no (or almost no - depending on the model) individual LEDs are visible and a continuous coloured light band is created. Nevertheless, NEONFLEX strips can still be bent easily and curves or even large-format lettering and logos can be created very well. However, pay attention to the bending orientation of the NEONFLEX strips! Some can be bent horizontally (e.g. for lettering), others vertically.

When do I need IP20, IP54, IP67 or IP68 tapes?

The IP rating for LED strips (and also for many other products) describes the water resistance. In other words, whether an LED strip can be used outdoors in the rain or even underwater.

The vast majority of strips are classified IP20, i.e. they have no water protection whatsoever. For most applications, this is not necessary and additional IP protection would only increase costs and installation effort and (slightly) reduce service life and brightness.

However, if an LED strip is to be used outdoors, for example, it usually has to be rainproof. In this case, a degree of protection of min. IP23 is required, e.g. IP54 or IP67. IP67 is the most common. Usually, the LED strips have a silicone cover that protects the LEDs. With IP54, instead of the silicone cover, there is a silicone coating directly on the LEDs. The water resistance is the same and the strip is somewhat narrower because the silicone cover has been dispensed with. However, it is very difficult and time-consuming to attach new connection cables to IP54 LED strips. For this purpose, the entire silicone layer must be scraped off at the solder contacts. With IP67 LED strips, you only have to cut away the silicone cover a little.

Neither IP54 nor IP67 are suitable for permanent underwater use! For example, in a pool. In this case, IP68 tapes must be used, where a silicone coating is combined with an additional silicone cover.

LED strips according to customer specifications

You need special LED strips or LED panels according to individual specifications? E.g. with a special LED mix or in certain brightness levels, colour rendering qualities, as BiColor, RGB + WW + CW or with a certain number of LEDs?

LED-Studien can have these individual LED strips or LED panels manufactured for you. Just talk to us.